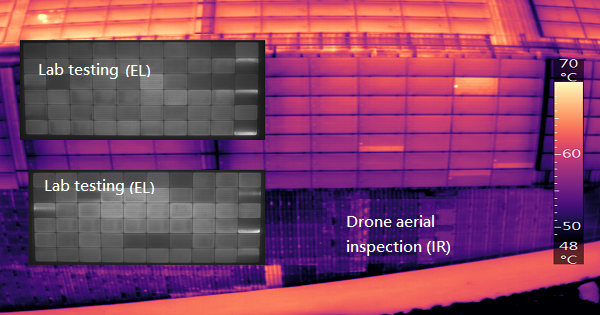

Drone aerial inspection to laboratory sample testing

IRUAV PLATFORM’s cloud-based visualization system enables precise classification and localization of defects detected during aerial inspections. Recently, we analyzed a rooftop PV system in Kaohsiung, Taiwan. A aerial inspection conducted in 2024 revealed that 1.28% of the modules exhibited substring open-circuit issues. To validate these findings, randomly sampled several anomalous modules in 2025 and sent them to the PV Laboratory at the Telecommunication Technology Center in Lujhu, Kaohsiung for electroluminescence (EL) testing. All six tested samples exhibited abnormalities, confirming the issue with 100% accuracy. Preliminary EL analysis suggests that rooftop PV modules experience greater thermal cycles between day and night compared to ground-mounted or floating solar systems. After eight years of operation and thousands of thermal cycles, the connection points between the busbars and interconnections within the modules may have loosened, increasing resistance. This heightened resistance generates forward bias voltage during operation, triggering diode activation. If a single diode is activated, the module loses one-third of its power output, and in severe cases, an entire module may cease power generation. This case highlights the benefits of combining aerial inspections with laboratory testing. Aerial inspection effectively identifies the percentage of anomalies (1.28% in this instance), while laboratory testing provide objective validation and deeper insights (pinpointing potential reliability concerns within the modules in this instance). Those information will help in handling subsequent issues.