Third Party Periodic Thermal Imaging Aerial Photography to Enhance Photovoltaic System Power Generation Efficiency

During the operation of a solar power plant, the power generation will decrease year by year due to module deterioration, poor contact, hot spot, PID, inverter imbalance or DC terminal abnormality, etc. These defects are often difficult to detect with the naked eye and do not show up completely in the daily monitoring system. These defects are often difficult to detect with the naked eye and are not fully displayed in the daily monitoring system, thus causing many generation losses to accumulate unnoticed.

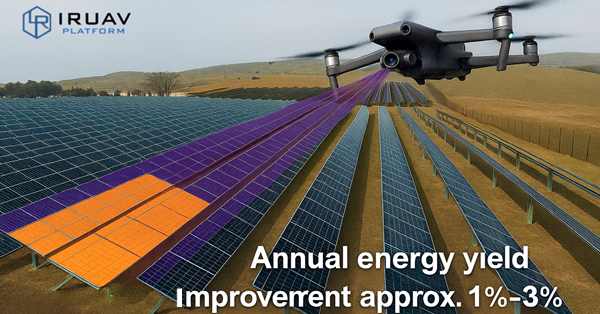

By conducting infrared thermographic inspections with drones (IR Thermography), an entire solar site can be scanned within a short period of time, allowing operators to quickly identify potential anomalies such as defective modules, string outages, overheating components, and early-stage degradation. International renewable energy organizations and leading operators — including NREL, Iberdrola, Enel, and ENGIE — have all highlighted in their published case studies that regular IR inspections are an essential measure for maintaining plant performance and improving annual energy yield.

According to international literature and IRUAV's actual project data of hundreds of MW, when third-party thermal imaging inspections are conducted at the site once or twice a year and appropriate repairs are carried out according to the inspection results, the energy loss caused by defects can be effectively restored, and the overall annual power generation can be increased by 1% to 3% on average; in the case of an old station that has not been inspected for many years, the improvement can even be as high as 3-5%. This not only improves power generation revenue, but also makes the condition of the equipment more transparent and traceable in ESG reports, insurance risk management, and long-term operating records.

As a result, thermal image aerial inspection has become a standard process for global energy companies to maintain system health, reduce maintenance costs, increase return on investment (ROI) and comply with ESG regulations. Through a data-driven, systematic inspection strategy, solar power systems can continue to operate in a more efficient, controlled and predictable manner.