Outdoor Photovoltaic System Diagnostics: Why IR is the world's 95% mainstream and EL is only 5%?

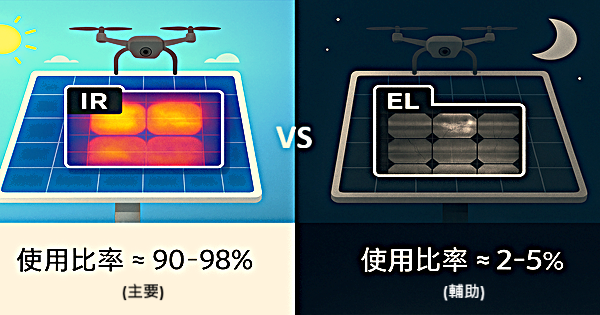

IR (Thermal Imaging) and EL (Electroluminescence) are key module diagnostic technologies in the outdoor inspection process of solar electric systems, but many people are still unclear about the difference between the two. According to a global survey, the utilization rate of IR is as high as 90 - 98%, while that of EL is only 2 - 5%. This difference is due to the different positioning of the two technologies in terms of usage conditions, efficiency, cost, technological threshold, and international standards.

I. Conditions of Use.

1. IR (thermal imaging) utilization ratio ≈ 90 - 98%

- It can be carried out during the daytime with no downtime and no power loss.

- The drone carrier can be used to quickly and safely scan a large area.

- It can detect most of the field defects: hot spot, PID, diode failure, shading, serial anomaly, wiring problem, etc. It is a mainstream tool for O&M worldwide.

- According to regional statistics, Europe and the United States are close to 100%; Japan: 95 - 98%; Taiwan: 90 - 95%.

2. EL (Electroluminescent) utilization ratio ≈ 2 - 5%

- Must be operated at night or in a low-light environment.

- Requires wiring and adding current, which is risky and time-consuming.

- Outdoor production capacity is very low.

- Costs 10 - 30 times that of IR.

- Main applications: warranty disputes, accident identification, COD sampling, microfracture detection.

II. Efficiency Differences.

An example is a 4 MW photovoltaic system (IEA PVPS Task 13 literature data):

- IR (drone carrier): 5 -10 hours (fastest)

- IR (handheld): 15 -20 hours

- EL (drone carrier): 20 - 40 hours

- EL (ground): 100 -150 hours (slowest)

- The EL process time is 4-10 times higher than the IR process time, and the cost is higher.

Technical thresholds.

- IR is ideal for routine inspections: fast, low-cost, and full coverage of defect types with AI or expert analysis.

- EL is suitable for high-precision identification of microcracks, hidden cracks, and warranty disputes that require visual evidence, but is not as authoritative as laboratory monolithic testing.

- For large PV plant (10 - 100 MW) it is almost uneconomical and operationally unfeasible to do a full EL check.

- IR = mainstream and regular inspections; EL = small fine-tuned tools, high operational thresholds, use in warranty disputes.

IV. Cost Comparison.

- IR: 1x (daytime shooting, fast, high coverage)

- EL: 10 - 30x (nighttime, wiring, high labor and low productivity)

- IR is almost the only logical choice for large plants.

V. Differences in emphasis.

- According to international O&M standards, 95% defects can be detected quickly by IR; EL is mainly used for microcracking or warranty disputes.

- IR is suitable for large-area thermal defect scanning; EL is used only in small quantities for special purposes.

- The high cost and low productivity of the EL makes it impossible to replace the IR as a routine inspection tool.

VI. International Standards .

1. IEC TS 62446-3:2017 - Photovoltaic systems - Thermal imaging.

IR is the official standard procedure for thermal image inspection of outdoor solar electric systems.

2. IEA PVPS Task 13 - Review on Infrared and Electroluminescence Imaging for PV Field Applications.

Specify that IR is suitable for fast scanning over large areas; EL requires a low-light environment and a high operating threshold.

3. C. Buerhop et al., IEA PVPS Report (2020).

Compare the efficiency, application limitations, and photo quality differences between IR and EL for outdoor use.

4. Recent EL Field Studies (2024 - 2025).

It was pointed out that outdoor EL is expensive, low capacity, requires professional staff, and is difficult to be commercialized for full-scale inspection.

VII. Overall conclusions.

IR = approx. 95% for outdoor inspection operations, which are efficient, economical and cover major defects.

EL = approx. 5% of auxiliary forensic tools for high precision and legal evidence requirements.

International PV O&M standards consistently use "IR as the primary method, EL as the secondary method" and position EL as an ad hoc use rather than a routine inspection method.