Effects of Twelve Thermal Defects on Power Generation in Solar Electric Systems

Solar module is the main unit of solar electric system to generate electricity, its function is to convert sunlight into electricity, if there is an abnormality that affects the conversion efficiency of solar module, the conversion of light energy into electricity will become less, according to the principle of conservation of energy, then additional thermal energy will be generated, which is what we call thermal defects. In other words, the existence of thermal defects will affect the power generation of the system. Smart O&M references IEC 62446-3 and categorizes thermal defects into the following 12 types according to the causes of thermal defects and their subsequent treatment:

| NO. | Thermal defect | Impact of PV module power | Remark |

|---|---|---|---|

| 1 | Modules in open circuit | 100% | The module does not generate power |

| 2 | Modules in short circuit | 100% | The module does not generate power |

| 3 | Broken front glass | 15.47% (rough estimate) | Apply the upper limit of the hot spot power loss |

| 4 | Substring in short circuit | 33.33% | 1/3 module does not generate power |

| 5 | One substring in open circuit | 33.33% | 1/3 module does not generate power |

| 6 | Two substrings in open circuit | 66.66% | 2/3 module does not generate power |

| 7 | Single cell with difference in temperature | 8.15% (average) | Overseas research on hot spot effect on power range: 0.83%~15.47% |

| 8 | Module with cells shaded | 8.15% (average) | Overseas research on hot spot effect on power range: 0.83%~15.47% |

| 9 | Bird dropping or dust | 8.15% (average) | Overseas research on hot spot effect on power range: 0.83%~15.47% |

| 10 | Transfer resistance at cell connections | 0.83% (rough estimate) | Apply the lower limit of the hot spot power loss |

| 11 | Heated module junction box | 0.83% (rough estimate) | Apply the lower limit of the hot spot power loss |

| 12 | Potential Induced Degradation | 50% (average) | Overseas research PID effect on power range: 30%~70% |

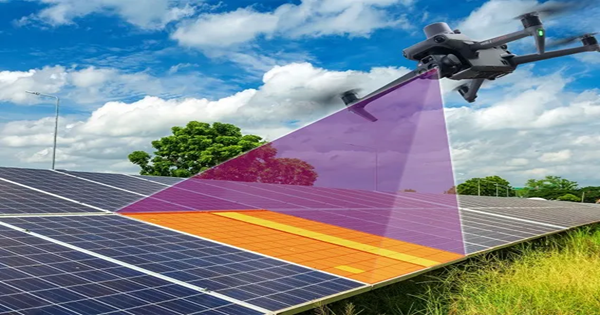

The table also lists the thermal defects on the solar module power impact of the estimation method, the table values refer to relevant foreign research, such as hot spots on the module power impact range of about 0.83% ~ 15.47%, potential difference caused by attenuation (PID) on the module power impact range of about 30% ~ 70%, the glass rupture may also produce a serious cell rupture, the cell welding high resistance value and the junction box high temperature phenomenon may be close to the lower temperature difference of hot spots on the power impact value is analogous to the upper and lower limits of the power impact value. Battery soldering with high resistance and junction box high temperature phenomenon may be close to the hot spot with lower temperature difference, and its power impact value is analogous to the upper and lower limits of the power impact range of the hot spot. The report in IRUAV APP will tabulate the detection rate of the above thermal defects in the field and the ortho-map module level localization.

It is worth noting that the above calculation method does not take series–parallel connections of modules into account, making it a relatively conservative way to estimate power loss. In reality, any abnormal module will affect other modules in the same string. For example, a module with broken glass, in addition to creating hot spots, may pull down the current of the entire string or, due to insulation resistance issues, cause the inverter to trip or start up late. This impacts a wider range of modules and tends to worsen over time. Therefore, once thermal defects are detected, early remediation is the best course of action.