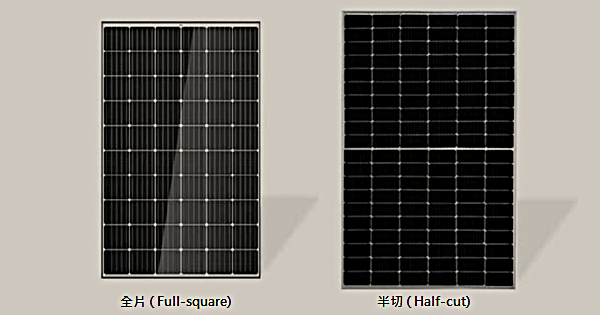

Full vs Half Cut Solar Module : Thermal Image Inspection Difference

Half-cut modules have become the mainstream of the market due to their high wattage and low cost per watt, and the way of reading thermal image inspection has changed accordingly. This article organizes the differences between full-chip and half-cut modules in thermal image inspection.

I. Major Differences in Thermal Imaging

Full-size (Full-square) module:

- The hot spots are concentrated and large.

- Temperature difference often exceeds 10-20°C.

- Defects are intuitive and easily recognizable.

Half-cut (Half-cut) module:

- The hot spots are smaller, more numerous and more scattered.

- It is often found in the upper or lower hemisphere.

- Temperatures tend to fall in the 5-10°C range.

Second, why does the half-cut module look less hot?

The half-cut module cuts the cell in half so that the current is diverted and the heat is proportional to the square of the current, so the heat is no longer concentrated, but it does not mean that the defects do not exist.

Impact on Inspection and Maintenance

- Full-size modules: quick and easy to determine by on-site personnel.

- Half-cut module: Higher reading threshold due to current shunt effect.

IV. CONCLUSION

The heat defect patterns of full-chip and half-cut modules are not the same in the shade condition. The complexity of the half-cut module manufacturing process is higher, and the structure of the module is smaller in size, making it easier for the diode to open and change the direction of the current flow, which affects power generation but helps to minimize the risk of fire caused by the hot spot of the module.