Difference between Thermal Imaging Aerial Inspection and SolarEdge

One advantage of power optimizers in PV systems is their ability to continuously monitor module performance during operation. In May 2020, SolarEdge Technologies published a technical white paper titled “Power Optimizers Match Infrared (IR) Imaging Capabilities at Finding Module Defects”. The study compared thermal aerial inspections with power optimizer monitoring in detecting module anomalies. The conclusion was that both methods are equally effective in identifying abnormal modules.

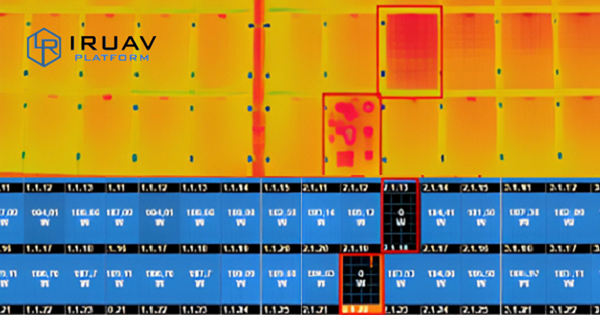

In the study, a 25 kW rooftop PV system that had been in operation for about six years and was equipped with SolarEdge Power Optimizer was inspected using thermal aerial imaging inspection. The system already had some known module anomalies. The optimizer app showed that certain modules were generating only about two-thirds of the power output of normal modules. The thermal aerial inspection revealed “substring open-circuit” thermal defects on the same modules, indicating abnormal bypass diode conduction. Additionally, two modules that appeared as “no power generation” on the optimizer app were identified through thermal imaging as having “open-circuit” and “short-circuit” failures, respectively.

This case shows that power optimizers and thermal aerial inspections have comparable effectiveness in identifying abnormal modules, but it also highlights their respective advantages and limitations. Advantages of power optimizers: (1) Continuous monitoring during operation. (2) Real-time detection of anomalies. (3) Records power loss directly. Disadvantages of power optimizers: (1) Additional installation and maintenance costs. (2) Cannot directly identify the physical failure mode. Advantages of thermal aerial inspections: (1) Much lower cost compared to optimizers (2) No risk of optimizer malfunction. (3) Can directly show the physical failure mode. Disadvantages of thermal aerial inspections: (1) Require piloting and inspection skills. (2) Anomalies can only be found during the inspection. (3) Image interpretation requires professional knowledge. (4) The exact time of anomaly occurrence is difficult to determine.

In recent years, the number of medium- and large-scale PV systems (in the megawatt range) has continued to grow. For monitoring modules in these large-scale fields, thermal aerial inspections have a clear cost advantage, making them a highly attractive option. However, such large-scale systems also impose higher operational requirements on thermal aerial inspections. If only drones are used, without AI-based thermal defect analysis and a visualization platform, the workload becomes heavy and the error rate can be high. IRUAV PLATFORM provides functionality similar to the SolarEdge Monitoring Platform, enabling low-cost thermal aerial inspections to achieve high-quality and accurate results.